Essential Guide to Warehouse Line Marking

Essential Guide to Warehouse Line Marking UK

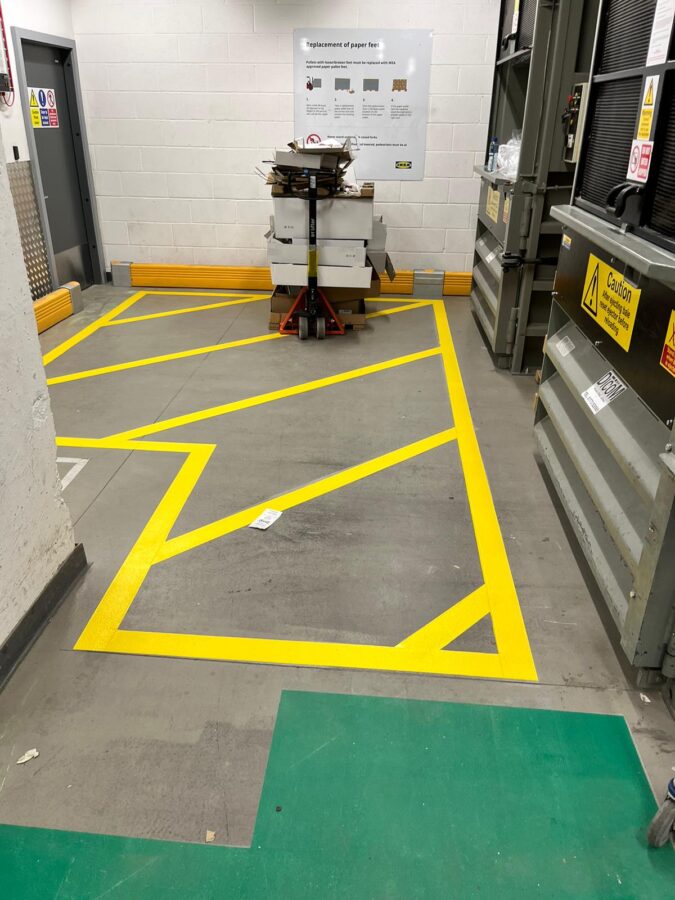

In a busy warehouse environment, safety and efficiency are everything. With the constant flow of goods, forklifts, and people, clear organisation is essential. One of the most effective ways to achieve this is through warehouse line marking.

By implementing well-planned floor markings, you can reduce risks, improve workflow, and create a safer, more efficient workplace. This guide explains why line marking is so important, the best materials to use indoors, and how to ensure your markings last.

Why Warehouse Line Marking Matters

Warehouse line marking is not just about painting lines — it’s about creating a structured, safe and productive environment.

- Safety: Clearly marked walkways, forklift lanes, and hazard zones reduce the risk of collisions and accidents.

- Organisation: Line marking designates zones for storage, loading, and unloading, helping goods and staff move seamlessly.

- Efficiency: With defined routes and areas, employees spend less time navigating and more time working.

Done correctly, line marking improves compliance with health and safety standards while also boosting productivity.

The Best Paint Types for Warehouses

Because warehouses are indoor environments, durable paints designed for interior use are essential. Here are the most common options:

- Epoxy Coatings

- Extremely durable and resistant to abrasion, chemicals and forklift traffic.

- Best suited for heavy-duty warehouses, logistics hubs, and production facilities.

- Polyurethane Paints

- More flexible than epoxy, with excellent impact and chemical resistance.

- Ideal for areas exposed to machinery vibration or where a less brittle surface is needed.

- Solvent-Based Paints

- Hard-wearing, fast-drying, and resistant to oil and cleaning chemicals.

- Great for medium to high-traffic areas with frequent cleaning.

- High-Quality Water-Based Paints

- Eco-friendly and cost-effective, with low odour and VOCs.

- Suitable for light to medium traffic zones or areas needing quick application.

- Floor Marking Tape

- Flexible, quick to install, and easy to remove or replace.

- Best for temporary layouts or frequently reconfigured spaces.

???? For advice on the right materials for your facility, see our line marking paint guide.

Best Practices for Effective Line Marking

To get the best results, warehouse line marking should follow some proven principles:

- Plan Your Layout

Map out traffic routes, storage zones, and pedestrian walkways before applying markings. Involve safety officers and warehouse managers to ensure all operational needs are covered. - Follow Colour Codes

- Yellow: Pedestrian walkways or caution zones.

- Red: Fire exits, fire equipment, and danger zones.

- White: General demarcation and storage boundaries.

- Blue/Green: Specific operational or safety zones.

Consistency is key so staff instantly understand the markings.

- Use Symbols and Signage

Reinforce lines with arrows, hazard symbols, and safety signage for maximum clarity. - Train Staff

Make sure employees know what each marking means. Training improves compliance and reduces risk.

Maintenance and Longevity

Even the best markings wear down under forklift tyres, pallet trucks, and cleaning equipment. Regular maintenance keeps your lines sharp and safe.

- Inspect regularly and schedule touch-ups before lines become unclear.

- Clean floors to prevent dirt and oil from reducing visibility.

- Refresh high-traffic areas more frequently than low-use zones.

Proactive maintenance prevents safety hazards and avoids costly downtime.

Why Hire Professional Contractors

While some businesses attempt DIY marking, professional line marking contractors deliver:

- Precision: Clean, straight lines applied with specialist equipment.

- Durability: Use of high-quality industrial paints suited to your floor conditions.

- Compliance: Knowledge of UK health and safety requirements.

- Efficiency: Minimal downtime thanks to expert scheduling and application.

Our team at Line-Mark.com provides tailored solutions for warehouses across the UK, ensuring your facility stays safe, organised, and compliant.

Conclusion

Warehouse line marking is an investment in safety, organisation, and efficiency. By choosing the right materials — such as epoxy, polyurethane, solvent-based or water-based paints — and following best practices for layout and maintenance, you can transform your warehouse into a safer and more productive environment.

For professional warehouse line marking UK, contact Line-Mark.com today.